BMP has set up a fantastic Powder Coating Production Line for our fencing and other metal products. This is like a big machine that puts a special coat on different things, like metal parts, to make them stronger and look nicer. Let's explore how this system works and why it's so great.

Step-by-Step Journey in Powder Coating

Getting Ready: First, BMP makes sure everything to be coated is clean and ready. This means getting rid of any dirt or grease that might be on the items.

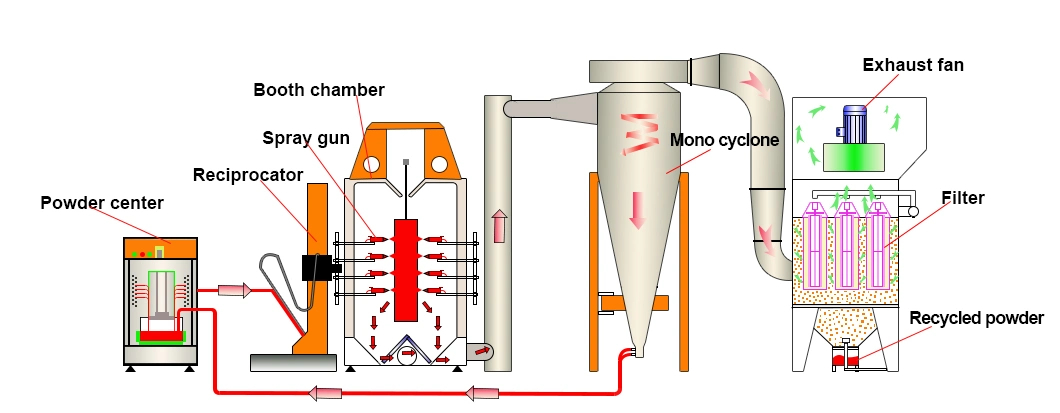

The Powder Coating Booth: Here's where the magic happens! In a special booth, they spray a kind of powder onto the items. This powder sticks to the items because of an electric trick – it's a bit like when a balloon sticks to a wall after you rub it on your hair.

Baking Time: After the items are all covered in powder, they go into a big oven. The heat in the oven makes the powder melt and stick to the items, forming a tough and smooth layer.

Cooling Down: Once the coating is baked on, the items need to cool down. This helps the new coat settle and become really strong.

The Magic of Powder Coating

Powder coating is a remarkable process that involves applying a protective and decorative finish to a wide range of materials. This technique uses a powder material, which is applied as a dry powder and then cured under heat to form a 'skin.' It's a process known for its durability and high-quality finish, making it a popular choice in various industries.

Applications in Fencing: BRC, 358, and More

One of the standout applications of powder-coated production lines is in the world of fencing. Here's how it transforms different types of fencing:

BRC Fencing: This fencing, known for its sturdy wire mesh design, gains enhanced durability and weather resistance from powder coating. The coating ensures that these fences can withstand harsh conditions without rusting or losing color.

358 Fencing: Often used in high-security areas, 358 fencing benefits immensely from powder coating. The coating adds an extra layer of protection, making it more resistant to cutting and ensuring it remains strong against environmental elements.

Clear View Fencing: For clear view fencing, which is all about aesthetics without compromising security, powder coating is a game-changer. It provides a sleek, uniform finish that is both appealing and resistant to wear and tear.

NYLOFOR Fencing: NYLOFOR fencing, recognized for its rigidity and strength, becomes even more robust with a powder coat. The coat not only adds to its strength but also offers a range of color options for aesthetic flexibility.

Extending to Dog Kennels

Even beyond fencing, powder coating finds its application in creating durable and safe dog kennels. Welded mesh dog kennels coated with powder not only look great but are also safer for pets. The smooth, consistent coating prevents injuries that might occur from sharp edges and also makes the kennels easier to clean and maintain.

The Benefits That Make a Difference

The advantages of using a powder-coated production line are numerous:

Durability: Powder coating creates a hard finish that is tougher than conventional paint, making products more resistant to scratches, chipping, fading, and wear.

Eco-Friendly: Unlike traditional liquid paint, powder coating doesn't involve harmful chemicals or solvents, making it a more environmentally friendly option.

Cost-Effective: While providing superior quality, powder coating is also cost-effective in the long run due to its durability and low maintenance requirements.

Aesthetic Flexibility: With a variety of colors and finishes available, powder coating allows for greater creativity and customization in design.

Protection: It offers enhanced protection against rust and corrosion, especially important for outdoor applications like fencing and kennels.

The Process Flow of Powder Coating Production

The powder coating production line follows a meticulous process to ensure the highest quality finish. It starts with the pre-treatment of the workpiece, including degreasing, water rinsing, and phosphating. After pre-treatment, the workpiece enters a water drying oven to remove any moisture, preparing it for the next step. The powder coating booth is where the magic happens – using advanced reciprocators and powder coating guns, the workpiece receives an even and thorough coating. Finally, the powder curing oven bakes the workpiece, solidifying the coating for a durable finish.

Advantages of Using a Powder Coating Production Line

One of the most significant advantages of using a powder coating production line is its high efficiency. The automated nature of the line means a faster turnaround, allowing for high-volume production without sacrificing quality. Moreover, the line's design ensures a high utilization rate of the powder, reducing waste and making it a cost-effective solution.

The environmental benefits of the powder coating production line cannot be overstated. Unlike traditional liquid coatings, powder coatings do not contain harmful solvents, reducing the emission of volatile organic compounds (VOCs). This makes it a safer choice for both the environment and the workers.

Applications Across Industries

The versatility of the powder coating production line is evident in its wide range of applications. From automotive parts and aerospace components to everyday consumer goods and electronics, this technology ensures a high-quality finish across various products. Its ability to provide a uniform, durable, and attractive coating makes it ideal for industries where both aesthetics and functionality are key.

Ensuring Long-Term Business Success

Adopting the powder coating production line not only enhances the quality of your products but also establishes a foundation for long-term business success. By offering high-quality, durable, and eco-friendly solutions, businesses can stay ahead of the competition and meet the evolving demands of consumers.

Conclusion

The powder coating production line is more than just a piece of equipment; it's a gateway to improved efficiency, quality, and sustainability in manufacturing. Embracing this technology means taking a significant step forward in industrial production, offering numerous benefits to businesses and the environment alike.